Reliability test box popularity reliability test box on the impact of today's life and its importance

With the continuous progress of science and technology, human beings can set foot in more and more extensive space, from the tropics to the cold zone, from the plain to the plateau, the use of "transport tools" (cars) is more and more frequent.

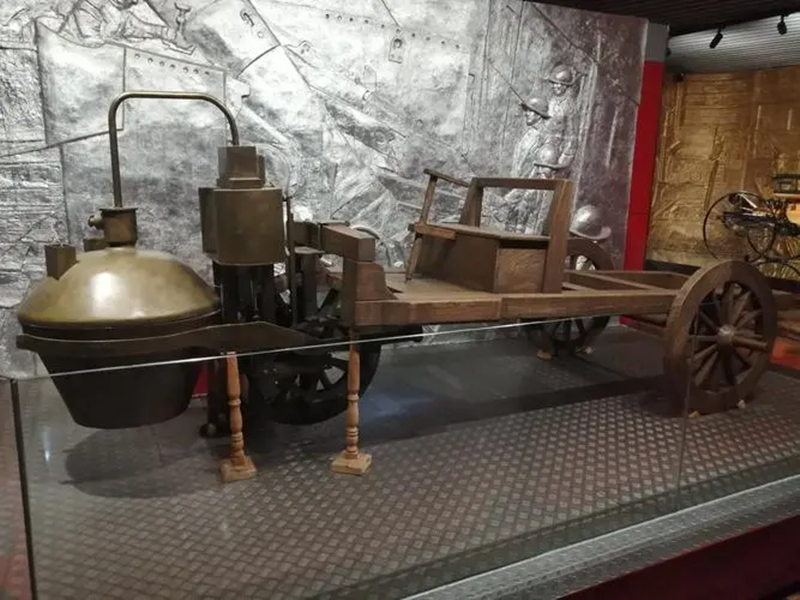

In 1769, the French artillery engineer nicolas Joseph JuNuo, made the first in the world to drive on its own power STEAM car, its purpose is not to civilian use, but in order to replace horses, to pull the heavy artillery, and since the power of the equipment from the "STEAM" (STEAM), so called "cars".

However, due to the science and technology is not developed at that time, the human use of science and technology also is quite elementary phase, the engineer of his own design also does not have enough environmental testing and simulation, finally because decorate in front of boiler is too heavy, not with a man's power to make equipment, there was a traffic accident, hit the wall. It was also the first "traffic accident" in the history of human automobiles. From this we can understand that the environmental test in the production of products, especially in the details of the product grinding has a very important role.

Environmental testing is the practice of exposing products to natural or artificially simulated conditions to evaluate their performance under conditions of storage, transportation and use that they may actually encounter. Through the environmental test, the adaptability and tolerance of the product under various environmental conditions can be observed, which can exclude early failure, fully expose the potential defects of the product, and provide information for the improvement of the product and the reduction of maintenance and guarantee costs. Able to provide validation data and valid information for failure analysis. In the "discovery - analysis - correction" cycle, constantly improve product quality.

Different environments have different effects on cars

High temperature environment (inside turbine engine) :

• Changes in electrical characteristics: impedance, inductance, capacitance, force rate, capacitance, etc

• Thermal aging: oxidation, cracking, chemical reaction

• Structural overloading and breakage due to physical expansion

• Changes in viscosity and evaporation of lubricants

• Expansion, softening, melting, sublimation, low viscosity

Low-temperature environment (bipolar survey) :

• Reduces the softness and fragility of resins and rubbers

• Increased gel and viscosity of lubricants

• Loss of mechanical strength due to physical contraction

• Icing, changes in electrical constants, cracks

High humidity environment (rainforest environment) :

• Absorption or absorption of water

• Increased conductivity of insulation

• Chemical reaction: corrosion, electrolysis

• Loss of mechanical strength

• Material expansion

Low humidity environment (desert environment) :

• Extreme low humidity causes embrittlement and granulation

• Loss of mechanical strength

• Evaporation, contraction, static electricity generation

• Increased wear of movable parts

Vibration environment (high-speed rail) :

• Physical structure damage

• Instruments and other equipment fail